SUINOX

We bring Specialized preventive and corrective maintenance services. for industrial equipment such as electric motors, gear motors, gear reducers, hoists, pumps, pistons, and hydraulic units.Our goal is to ensure the maximum efficiency, prolong the lifespan, of your equipment and prevent unexpected downtime in your operations.

We have trained technicians and advanced tools to provide accurate diagnostics and quick solutions. Keep your production running smoothly without interruptions!

An integral process that includes the installation of new bearing kits (FAG), seals, O-rings (neoprene), and gaskets (Teflon), as well as the replacement of the anti-spark mechanical seal and fasteners. A deep cleaning of the equipment is performed, followed by repainting, ensuring optimal performance and durability for industrial applications.

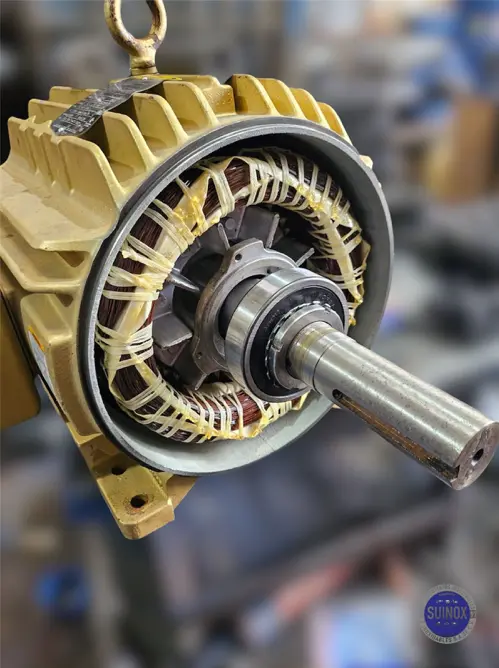

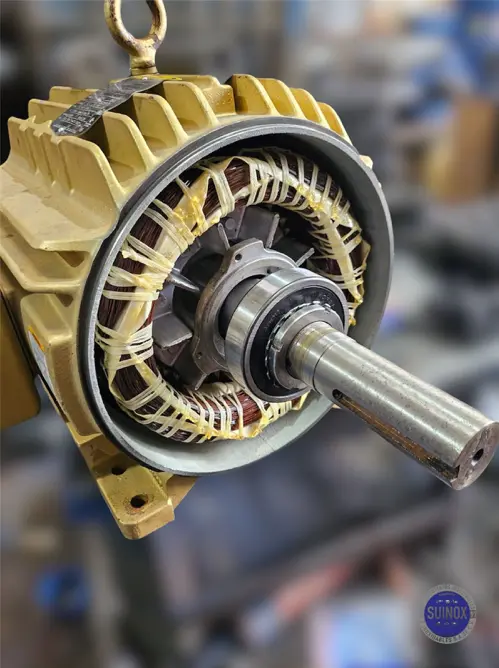

A complete service that includes cleaning with dielectric solvent, varnishing and baking, bearing replacement, and dynamic balancing of the rotor. It also involves the rectification of bearing housing boxes, deep cleaning of the exterior, and repainting, ensuring maximum performance and extending the motor's lifespan.

A complete service that includes cleaning with dielectric solvent, varnishing and baking, bearing replacement, and dynamic balancing of the rotor. It also involves the rectification of bearing housing boxes, deep cleaning of the exterior, and repainting, ensuring maximum performance and extending the motor's lifespan.

Manufacturing of a robust structure with 2-inch, 14-gauge PTR, using 7018 welding for maximum strength. Equipped with 16-inch heavy-duty ATR wheels. It finishes with a deep cleaning and application of paint for increased durability and aesthetics. Ideal for the safe and efficient transportation of pumping equipment.

Integration of the pump-motor unit using a Falk coupling on a solid structural base. This process includes a deep cleaning of the entire unit and the application of paint, ensuring precise alignment, durability, and optimal performance in industrial applications.

Integration of the pump-motor unit using a Falk coupling on a solid structural base. This process includes a deep cleaning of the entire unit and the application of paint, ensuring precise alignment, durability, and optimal performance in industrial applications.

Pump-motor installed on a robust transport trolley, designed with a high-strength PTR structure and heavy-duty wheels to facilitate mobility. Ideal for industrial applications that require versatile and efficient equipment.

• Bomba caracol centrifuga con impulsor de bronce, sello mecánico antichispa, 3” succión, 3” descarga.

• Cople unión engranado, marca Martin, situado en flechas.

• Tolva (cubierta) para coples.

• Motor eléctrico 15 hp.

• 1750 rpm.

• 220/440 volts.

• Tipo cerrado alta eficiencia, a prueba de explosión.

• Cuenta-galones de 3”, con filtro cedazo (reemplazable), y eliminador de gases.

• Montaje en base estructural (carro transportador) y ruedas uso rudo (4), para fácil manejo.

• Bomba caracol centrifuga con impulsor de bronce, sello mecánico antichispa, 3” succión, 3” descarga.

• Cople unión engranado, marca Martin, situado en flechas.

• Tolva (cubierta) para coples.

• Motor eléctrico 15 hp.

• 1750 rpm.

• 220/440 volts.

• Tipo cerrado alta eficiencia, a prueba de explosión.

• Cuenta-galones de 3”, con filtro cedazo (reemplazable), y eliminador de gases.

• Montaje en base estructural (carro transportador) y ruedas uso rudo (4), para fácil manejo.

Receive advice and discover the best solution, industrial product, and service for your business: